Electrical Control System Integration Solution for Construction Machinery

With the development of digitalization and Internet of Things (IoT), smart technology in construction machinery is highly demanded in recent years. To ensure safety in construction and economic benefits for customers, machines with reliability and adaptability are in need.

Huicheng has developed sophisticated solutions of electrical control system integration after years’ plunging in the construction machinery field. Partnered with many manufactures, Huicheng also gave them tailored solutions.

Pumps

ifm controllers with high performance and high protection rate are provided for concrete pumps working in different conditions. The shock and vibration resistant controllers, with IO-link and multiple communication interfaces, allows the pumps run in harsh conditions. Moreover, the acquisition of analog and communication signals from position and inclination sensors at the boom supports to realize the digital smart pumps. The integrated control system simplifies the complicated circuit, reduces the frequency of malfunctions and makes it easier to find faults when they occur.

- The system includes control and display units, sensor units, electrical control operating units and LED lights.

- The control and display unit is used to control the logic, manage parameter, diagnose fault and display.

- The operating unit is composed of integrated control module and toggle switch, and the illumination includes lights on leg and hopper.

- Offer products and service as customers required.

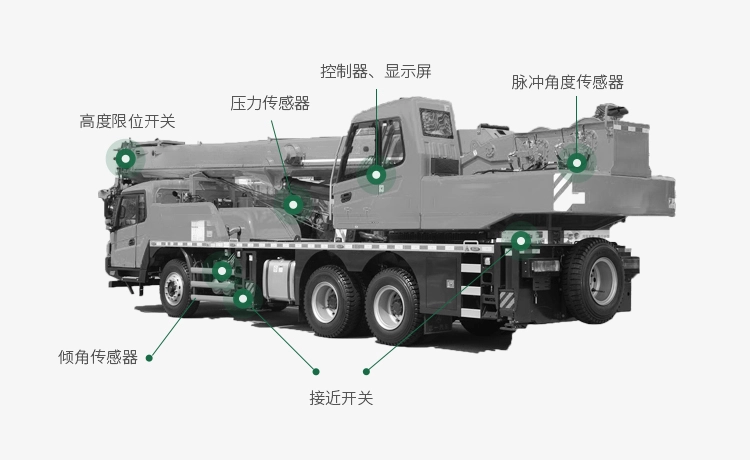

Cranes

ifm's controllers with many multifunctional configurable input and output channels, high-performance CAN interfaces for various communication tasks, are used to control logic of vehichles/mobile machines, interact data and manage parameter. The programmable graphic display with clearly visible big colour display for visualising machine functions, showing the work status, position and parameter setting of the cranes. High-precision rotary encoders transmit accurate information about the position of the crane's turntable. Position limit switches provide safety for boom and rope movements.

- The system includes control and display units, sensor units and LED lights.

- The control and display unit is used to control logic function, manage parameter, diagnose fault and display.

- Sensors mainly detect the boom position, the cylinder traveling, rotation angle, fuel level and pressure.

- Offer products and service as customers required.

Excavators

A smart system for excavator is developed, mainly detects and collect data of excavator bucket, arm, turntable, horizontal position of the vehicle body and the posture data. The system, supporting excavators working in the most efficient and economical mode, has been adopted by many excavator manufactures home and abroad.

- The system includes controllers, integrated control modules, key switches, sensors and LED lights.

- Offer products and service as customers required.

Drills

ifm's controllers with many multifunctional configurable input and output channels, high-performance CAN interfaces for various communication tasks, are used to control logic of vehicles/mobile machines, interact data and manage parameter. The programmable graphic display with clearly visible big colour display for visualising machine functions, showing the work status, position and parameter setting of the rotary drilling rig. High-precision sensors can detect parameters like mast tilt, real-time pressure and temperature, guaranteeing safety during operation.

- The system includes a main controller, I/O module, displays and sensors.

- The system mainly detects data of temperature, pressure, speed of engines and the hydraulic system. It also sets key parameters.

- Offer products and service as customers required.

Related Products

Cooperative manufacturers